Pipeline Pigging Services

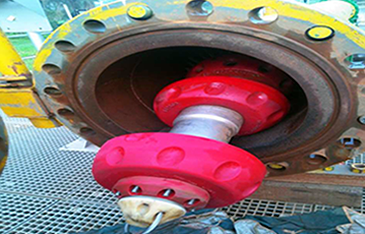

Pigging in the context of pipelines refers to the practice of using devices known as “pigs” which is an acronym for Pipeline Internal Diameter Gauge‖ to perform various maintenance operations. This is done without stopping the flow of the product in the pipeline. These operations include but are not limited to cleaning and inspecting the pipeline.

This is accomplished by inserting the pig into a “pig launcher” (or “launching station”) — an oversized section in the pipeline, reducing to the normal diameter. The launching station is then closed and the pressure-driven flow of the product in the pipeline is used to push the pig along down the pipe until it reaches the receiving trap — the “pig catcher” (or “receiving station”).

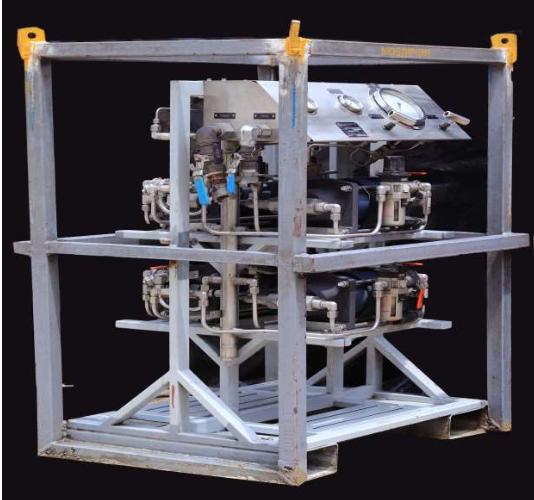

Hydrotesting Services

On completion of the cleaning, gauging and filling operations, the pipeline shall then be filled to eradicate all air bubbles, and be tested to the specified test pressures (Design pressure x 1.4) and held for 24 hours or less depending on client specifications. This operation shall be performed using a highpressure test pump spread located at one end of the pipeline (Launching end). In the course of hydrotesting operation, water shall be sourced from either the sea water or any hydrant sources as the case maybe. With regards to sea water, mesh size filters and chemically dosing will be required according to client specification. Detailed sequence of operational procedure shall be provided on case-by-case basis.

BULK DEWATERING

1st Bidirectional Pig

2nd Bidirectional Pig

3rd Bidirectional Pig

FINAL DEWATERING

1ST High sealing Bidirectional Pig

2ND High Sealing Bidirectional Pig

3RD High Sealing Bidirectional Pig

Drying Services

The drying operation starts once the final dewatering is accomplished. The drying process involves the use of super dry compressed air to run couple of foam pigs through the pipeline, ranging from medium density foam pigs to soft foam pigs. These foam pigs will be run continuously until a dew point of 20C is accomplished, then the pipeline will be considered dry and ready for commissioning through the use of nitrogen. The typical drying sequence of operation is as shown below

DRYING PIG RUN SEQUENCE

1ST Medium Density Foam Pig

2ND Medium Density Foam Pig

3RD Medium Density Foam Pig

4TH Medium Density Foam Pig

1ST Soft Foam Pig

2ND Soft Foam Pig

3RD Soft Foam Pig

4TH Soft Foam Pig